September 25, 2025

Cold Chain Excellence Under Extreme Weather: Advanced Storage Solutions for UAE’s 50°C Summer Challenge

During the UAE’s blistering summer months, ambient temperatures can soar above 50°C, imposing severe stress on food supply chains. In this environment, maintaining cold chain integrity is not merely a best practice—it is a critical requirement for food safety, product quality, and regulatory compliance. For distributors operating in the Emirates, advanced storage solutions and robust operational protocols are essential to prevent spoilage, safeguard consumer health, and uphold brand reputation.

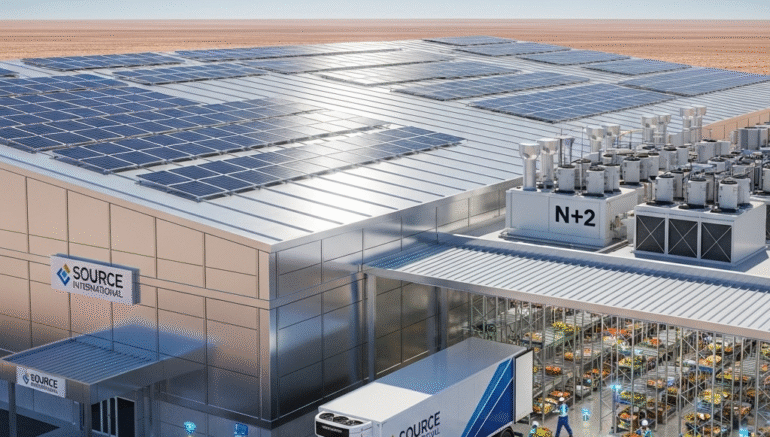

Source International (sourceinternational.ae), a leading food distribution partner in the UAE, has invested heavily in specialized infrastructure, technology, and processes to deliver cold chain excellence even under the most extreme weather conditions. This comprehensive overview examines the unique challenges posed by 50°C summer temperatures and the advanced storage solutions that ensure uninterrupted temperature control from port to plate.

1. Extreme Temperature Risks to Food Quality

At temperatures exceeding 50°C, perishable products—including dairy, meat, seafood, fruits, and vegetables—face accelerated microbial growth, enzymatic degradation, and rancidity. Specific risks include:

- Milk and Dairy Spoilage: Psychrotrophic bacteria thrive in inadequate refrigeration, leading to off-flavors and potential health hazards.

- Meat and Seafood Deterioration: Proteolytic enzymes break down muscle fibers rapidly at elevated temperatures, compromising texture and safety.

- Fresh Produce Wilting: Cellular respiration rates increase, causing rapid moisture loss and softening of fruits and vegetables.

- Frozen Food Thawing: Even brief temperature excursions can lead to partial thawing and refreezing, resulting in texture damage and freezer burn.

To mitigate these risks, distribution networks require storage facilities and transport equipment that maintain consistent temperatures—even when external heat loads are extreme.

2. Purpose-Built Cold Storage Facilities

Source International’s flagship cold storage facility in Jebel Ali Free Zone exemplifies best-in-class design and engineering for extreme climates:

High-Performance Insulation and Wall Systems

- Vacuum-Panel Insulated Walls: Panels with a thermal conductivity rating of 0.002 W/m·K minimize heat infiltration.

- Panoramic Thermal Curtains: Automated high-speed doors with multi-layer PVC curtains reduce air exchange during forklift traffic.

- Reflective Roofing Membranes: White, reflective roof coatings deflect solar radiation, lowering roof surface temperatures by up to 15°C.

Zoned Temperature Control

Dedicated rooms maintain precise temperature zones:

- Frozen Zone (–18°C): Independent refrigeration circuits with parallel cooling loops ensure redundancy if a compressor fails.

- Chilled Zone (2–4°C): Dual-cascade evaporator systems deliver accurate temperature control for dairy, meats, and fresh produce.

- Ambient Buffer Zone (10–15°C): Transitional storage mitigates temperature shock when moving products between zones.

Redundant Cooling Systems

- N+2 Compressor Configuration: Two extra compressors beyond the minimum required provide failover capability, guaranteeing uninterrupted cooling even during maintenance or breakdowns.

- Automated Load Sharing: Variable-speed drive compressors adjust capacity based on real-time thermal loads, optimizing energy consumption and maintaining setpoints within ±0.5°C.

3. Advanced Monitoring and Alert Systems

Maintaining cold chain performance in 50°C heat necessitates continuous monitoring and rapid response:

Internet of Things (IoT) Sensor Network

- Wireless Temperature and Humidity Sensors: Deployed every 50 square meters to capture micro-environment variations.

- Door-Open Event Detection: Magnetic sensors log every door opening and duration, triggering alert notifications if thresholds are exceeded.

- Real-Time Data Streaming: Sensor readings transmitted every minute to a centralized control dashboard.

AI-Driven Anomaly Detection

- Machine Learning Algorithms: Analyze historical temperature and energy usage data to establish normal operating patterns.

- Predictive Alerts: When a temperature deviation is detected, predictive models estimate potential escalation, prompting pre-emptive corrective actions before product integrity is compromised.

- Automated Escalation Protocols: Alerts escalate through SMS, email, and mobile app notifications to facility managers and maintenance teams.

4. Hybrid Energy Solutions for Resilience

Maintaining consistent refrigeration under extreme ambient heat places enormous demands on electrical infrastructure. Source International incorporates hybrid energy systems to ensure reliability and sustainability:

Solar-Assisted Cooling

- Photovoltaic (PV) Panels: A 500 kW rooftop solar array supplies up to 20% of daily energy needs for refrigeration compressors during peak sunlight hours.

- Thermal Storage Tanks: Sun-heated glycol buffers store thermal energy to assist chillers during evening peak demand, reducing grid reliance.

Backup Power and Generators

- Tier-3 UPS Systems: Uninterruptible power supplies provide up to two hours of critical load support for control systems and monitoring networks.

- Standby Diesel Generators: Three 1 MW generators engage automatically within seconds of grid failure, ensuring continuous operation of compressors and fans.

5. Specialized Transport and Last-Mile Delivery

Extreme warehouse performance must extend seamlessly into transport to prevent temperature excursions during last-mile deliveries:

Insulated Multi-Temperature Trucks

- Multi-Compartment Refrigerated Units: Trucks configured with separate frozen, chilled, and ambient compartments, each with its own refrigeration system.

- Enhanced Insulation: 120 mm sandwich-panel walls and ceilings ensure minimal heat gain over long distances.

- Remote Data Logging: GPS-enabled telematics record compartment temperatures, door events, and route progress in real time.

Rapid Loading and Unloading Protocols

- Pre-Chilling Docks: Loading bays maintained at 10°C to minimize thermal shock during transfer.

- Timed Delivery Slots: Coordinated appointment windows optimize unloading efficiency and reduce door-open times in high-traffic retail environments.

- On-Board Genset Backup: Auxiliary power units supply refrigeration for up to four hours if the truck’s main engine is off during urban deliveries.

6. Employee Training and Operational Excellence

State-of-the-art infrastructure must be complemented by rigorous operational protocols and staff expertise:

Certified Cold-Chain Management Programs

- HACCP-Aligned Training: Employees complete comprehensive courses on hazard analysis, critical control points, and sanitation in high-temperature environments.

- Temperature-Control Best Practices: Hands-on instruction in sensor placement, equipment startup/shutdown procedures, and emergency response drills.

Standard Operating Procedures (SOPs)

- Loading Checklists: Verify compartment pre-cooling, sensor calibration, and door seal integrity before dispatch.

- Weekly Maintenance Regimens: Preventive checks on compressor oil levels, refrigerant pressures, insulation integrity, and sensor accuracy.

- Monthly Emergency Drills: Simulated power failures and equipment malfunctions to test backup systems and response coordination.

7. Sustainability and Regulatory Compliance

Sustaining cold chain excellence in extreme heat must align with environmental and regulatory expectations:

Energy Efficiency Metrics

- Coefficient of Performance (COP) Targets: Regular auditing ensures refrigeration systems operate at or above a COP of 4.0.

- Demand-Response Participation: Facilities adjust non-critical loads during utility peak events in exchange for tariff incentives and grid support payments.

Regulatory Inspections and Certifications

- ISO 22000 and HACCP Accreditation: Annual audits verify food safety management systems, temperature control documentation, and traceability protocols.

- Municipal and Federal Compliance: Submission of monthly energy usage and refrigeration maintenance reports to local authorities demonstrates adherence to environmental and safety standards.

8. Customer Engagement and Confidence

Ultimately, cold chain excellence under extreme temperatures translates into customer trust, reduced waste, and stronger brand loyalty:

- Real-Time Client Portals: Retailers and HORECA clients access live dashboards showing storage room and in-transit temperatures, delivery schedules, and quality certificates.

- Custom Reporting and Analytics: Detailed monthly reports highlight performance against temperature KPIs, energy consumption, and downtime incidents.

- Joint Business Reviews: Quarterly meetings with key clients review operational metrics, forecast seasonal volume changes, and plan capacity requirements for peak summer months.

Conclusion and Call to Action

With 50°C summer temperatures posing unprecedented challenges to food quality and safety, exceptional cold chain infrastructure and operational rigor are non-negotiable. Source International’s integrated approach—combining purpose-built facilities, advanced monitoring, hybrid energy systems, specialized transport, and rigorous training—ensures resilient, uninterrupted temperature control across the entire distribution network.

Partner with Source International to secure your supply chain against extreme weather risks and guarantee the highest standards of food safety and quality:

- Explore our cold chain capabilities and facility tours: https://sourceinternational.ae/services/

- Read detailed case studies on extreme-heat performance: https://sourceinternational.ae/why-source-international-leads-the-uae-food-distribution-landscape-in-2025/

Ensure your products remain safe, fresh, and compliant all summer long—contact Source International today for a customized cold chain resilience assessment and discover how we keep your supply moving, no matter how high the mercury climbs.